Deep analysis of rated capacity and load capacity of transformers

Writer: Hengfeng you electric Time:2023-05-06 views:times

A

transformer is a static electrical appliance that converts AC energy of one voltage level into AC energy of another voltage level at the same frequency through electromagnetic induction between coils

A transformer works using the principle of electromagnetic induction. It is composed of two windings that are insulated from each other and have unequal turns (forming a circuit), which are assembled on an iron core with good magnetic conductivity materials (forming a magnetic circuit). There is only magnetic coupling between the two windings and no electrical connection.

Rated capacity: Refers to a transformer that, under specified cooling conditions, can achieve economic and reasonable efficiency by carrying a load equal to the rated capacity for a long time, and the

temperature rise of each part does not exceed the standard requirements. That is, the insulation of the transformer has a normal aging rate under rated load and will not be damaged before its normal service life (usually 20-30 years).

Load capacity: Refers to the power output of a transformer in a short period of time, which may be greater than the rated capacity. Load capacity is the load capacity that can ensure the normal lifespan of the insulation materials in the transformer. (depending on the lifespan of the insulation material)

Compared to catalytic, hydrogenation, and sulfur transformers:

(1) Added oil storage tank

(2) Switch to a regular radiator

Expansion and contraction radiators, changes in oil volume are adjusted and compensated for by the elasticity of the fuel tank and radiator

In the closed oil circuit system of a transformer, convective circulation flows through changes in the buoyancy and gravity of the oil. That is, inside the transformer oil tank, the heating elements (such as windings and iron cores) surrounded by transformer oil heated the surrounding transformer oil. The density of the heated transformer oil became smaller and the buoyancy floated upward. The oil with lower temperature at the lower part replaced the floating oil, making transformer oil flow from bottom to top in the heating elements such as transformer windings and iron cores.

Where the surface heat flux density of the heating element is high, the oil flow rate will naturally accelerate. The hot oil flows into the radiator at the top of the oil tank, where the heat carried from the transformer winding and other heating elements is dissipated into the surrounding air through the external surface of the cooling element, making the oil temperature lower and the specific gravity larger, flowing downward under the action of gravity, and then flowing back to the lower part of the transformer oil tank, thus forming a natural convection circulation flow of transformer oil in its closed oil circuit system.

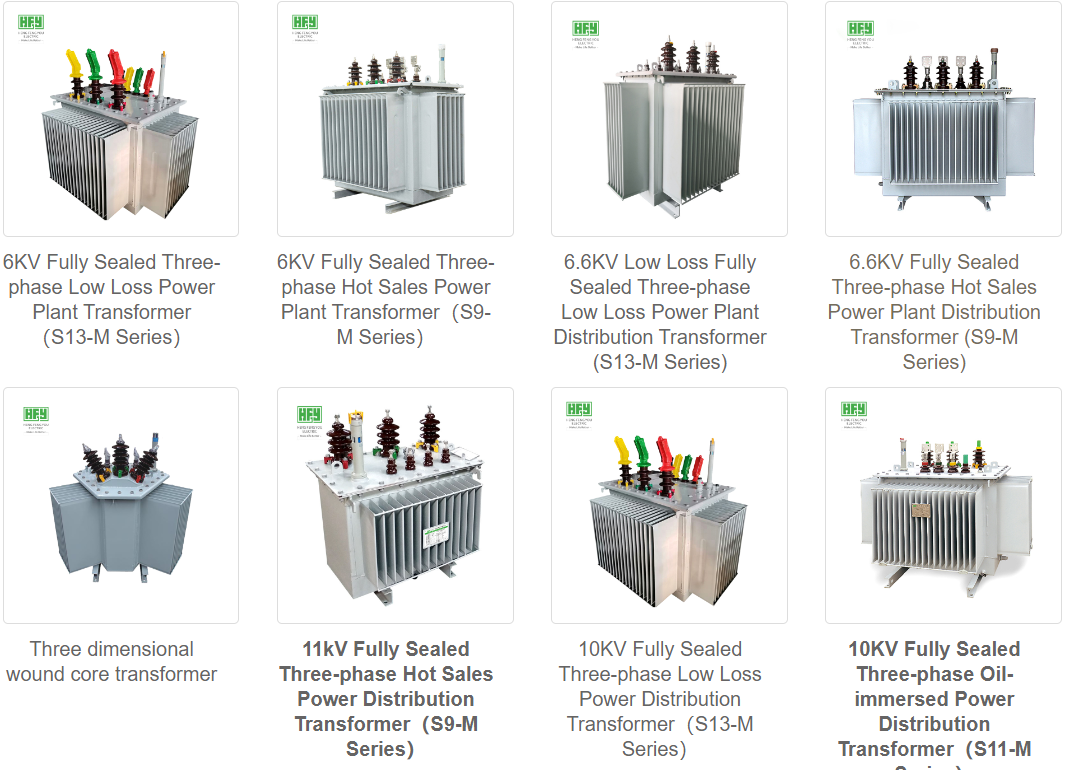

Hengfengyou is a professional electrical company specializing in the production, manufacturing and sales of electrical distribution products, mainly engaged in the production and global sales of distribution transformers, rectifier transformers, electric furnace transformers, etc. We have provided OEM / ODM services for customers in Europe, America and the Middle East for 20 years. It can provide customized production of transformer core, transformer coil and transformer shell. Hengfengyou Electric will provide you with the best electrical product solutions. https://www.hengfengyou.com ; info@hengfengyou.com WhatsApp:+86158 5325 2696(Jack) +86158 5326 5269(Alisa)

Hengfengyou is a professional electrical company specializing in the production, manufacturing and sales of electrical distribution products, mainly engaged in the production and global sales of distribution transformers, rectifier transformers, electric furnace transformers, etc. We have provided OEM / ODM services for customers in Europe, America and the Middle East for 20 years. It can provide customized production of transformer core, transformer coil and transformer shell. Hengfengyou Electric will provide you with the best electrical product solutions. https://www.hengfengyou.com ; info@hengfengyou.com WhatsApp:+86158 5325 2696(Jack) +86158 5326 5269(Alisa)