The Harm and Treatment Methods of Transformer Oil Leakage

Writer: Hengfeng you electric Time:2023-04-26 views:times

Based on years of production and manufacturing

transformer experience, Hengfengyou Electrical Engineer lists the following contents

1. Specific hazards of transformer leakage and oil leakage

1. The phenomenon of transformer oil leakage not only seriously affects the appearance, but also causes economic losses due to the need to shut down the transformer to eliminate leakage. If there are many oil stains on the ground foundation of the transformer, it may also become a potential fire hazard.

2. Oil leakage can seriously interfere with the monitoring and judgment of the sealing condition and oil level indicator accuracy of the transformer oil storage tank by operation and maintenance personnel.

3. After the oil level decreases due to leakage, it may cause live joints, switches, etc. to operate without oil insulation, which may lead to breakdown, short circuit, burning, and even equipment explosion.

4. After the transformer leaks oil, it will cause the fully sealed transformer to lose its sealing state, which can easily cause the oil paper insulation to be affected by the invasion of external air and water, leading to a decrease in insulation performance, accelerating insulation aging, and affecting the safe and reliable operation of the transformer.

In addition, when the sealing of the top vent plug, sleeve conductive head, and other parts of the oil storage tank is damaged, or there are sand holes on the top of the oil storage tank and its connecting pipes, even if there may not be oil leakage due to the high position, it may enter rainwater and moisture, leading to deterioration of insulation performance, and even causing insulation breakdown and winding burning accidents.

2. Measures for Treating Transformer Leakage and Oil Leakage

Before dealing with oil leakage, it is necessary to carefully analyze and identify the cause and exact point of leakage. For existing oil stains, first clean with cleaning agent, rinse with clean water, and finally repeatedly wipe with a clean cloth to find the exact location of the leakage point.

①. Using Welding to Control Transformer Oil Leakage

When oil leakage is found on the upper part of the transformer oil tank, only a small amount of oil needs to be drained before welding; When leakage is found in the lower part of the oil tank, due to the large waste of hanging core oil discharge and the limitations of on-site conditions, welding with oil can be used for treatment. Repair welding with oil should be carried out when the oil leakage is not significant, otherwise the vacuum drainage method should be used to cause negative pressure before welding. The vacuum degree of the negative pressure should not be too high, and it is advisable to have equal internal and external pressures to avoid inhaling molten iron. When repairing welding, the oil stains on the welding area should be removed thoroughly, and it is best to rinse with alkaline water before wiping dry; During the welding process, attention should be paid to preventing penetration and ignition, and the welding site must be below the oil level; During welding, intermittent and rapid spot welding should be used, and the arc ignition time should be controlled within 10-20 seconds. Long term continuous welding is absolutely not allowed.

When repairing pores with severe oil leakage, iron wires or other materials can be used to block or rivet them before welding; When welding near sealing rubber gaskets or other vulnerable components, cooling and protective measures should be taken.

Some netizens generally believe that the transformer body and accessories have oil leakage, and the transformer core must be lifted out and cleaned of oil before welding. Although this method is safe, it is time-consuming and labor-intensive, and can also affect electricity consumption.

Some people are afraid of causing transformer oil to catch fire. In fact, this fear is superfluous. Oil burning requires certain conditions, temperature and oxygen. However, when welding on the transformer body with oil, the oil will circulate convection when it is heated, and will lose heat quickly. Besides, there is no oxygen in the oil tank, so the transformer with oil leakage repair will not burn. However, the leaked oil is prone to combustion, and the airflow generated by combustion makes it difficult for the welding rod solution to fall into the cracks, resulting in welding difficulties.

Can this difficult problem be solved? Here are the specific methods for repairing transformer leakage with oil:

(1) According to the characteristics that the heat will dissipate quickly when repairing with oil, arc welding welding shall be used for repair, and gas welding shall not be used.

(2) In order to prevent the leaked oil from vaporizing and hindering welding, asbestos rope or other softer ropes can be used to plug the leakage joint before welding. For larger leaks, partial welding can be carried out, and when the leak is reduced to a single point, asbestos rope can be used to block the welding. If there is oil leakage from the device body, you can use a hammer to gently twist the oil leakage port and then weld it again.

(3) The welding speed should be fast. For large gaps in the oil leakage area, it is best to stop welding for a while, and the welding time should not exceed 20 seconds each time. Wait for a few minutes before welding and let the oil cool down for a while.

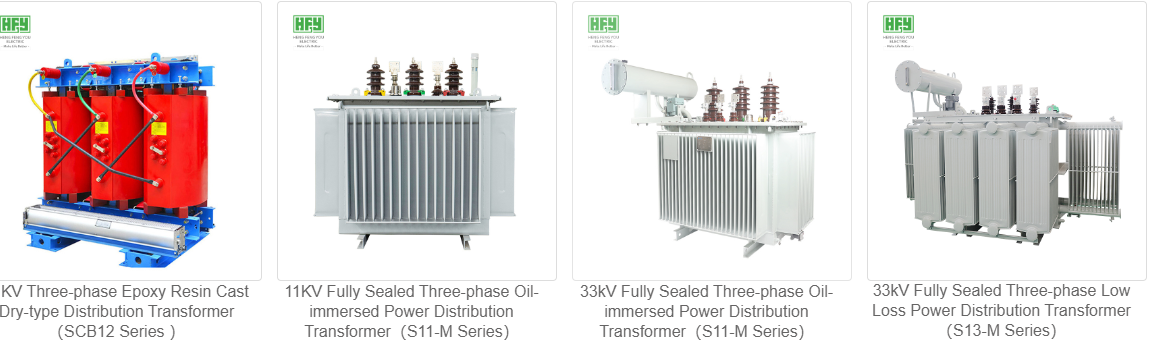

Hengfengyou is a professional electrical company specializing in the production, manufacturing and sales of electrical distribution products, mainly engaged in the production and global sales of distribution transformers, rectifier transformers, electric furnace transformers, etc. We have provided OEM / ODM services for customers in Europe, America and the Middle East for 20 years. It can provide customized production of transformer core, transformer coil and transformer shell. Hengfengyou Electric will provide you with the best electrical product solutions. https://www.hengfengyou.com ; info@hengfengyou.com WhatsApp:+86158 5325 2696(Jack) +86158 5326 5269(Alisa)